Using magnetic grippers with non-ferromagnetic payloads¶

FluxGrip is a magnetic system and thus requires a ferromagnetic surface to attach to. However, one should not be under the impression that this disqualifies non-ferromagnetic payloads: any arbitrary payload can be carried, as long as one uses an attachment piece.

The simplest possible design of said attachment piece is a ferromagnetic plate permanently attached to the payload. This approach, however, is not always feasible, as it requires modification of the payload.

Another approach is to use a multi-part attachment piece designed such that it grips the payload as long as the magnet remains magnetized, and releases it when the magnet is turned off. The principle is somewhat reminiscent of the reed relay (aka herkon). Importantly, this attachment piece stays with the magnet and does not require modification of the payload. At Zubax, this solution is referred to as TeslaClaw.

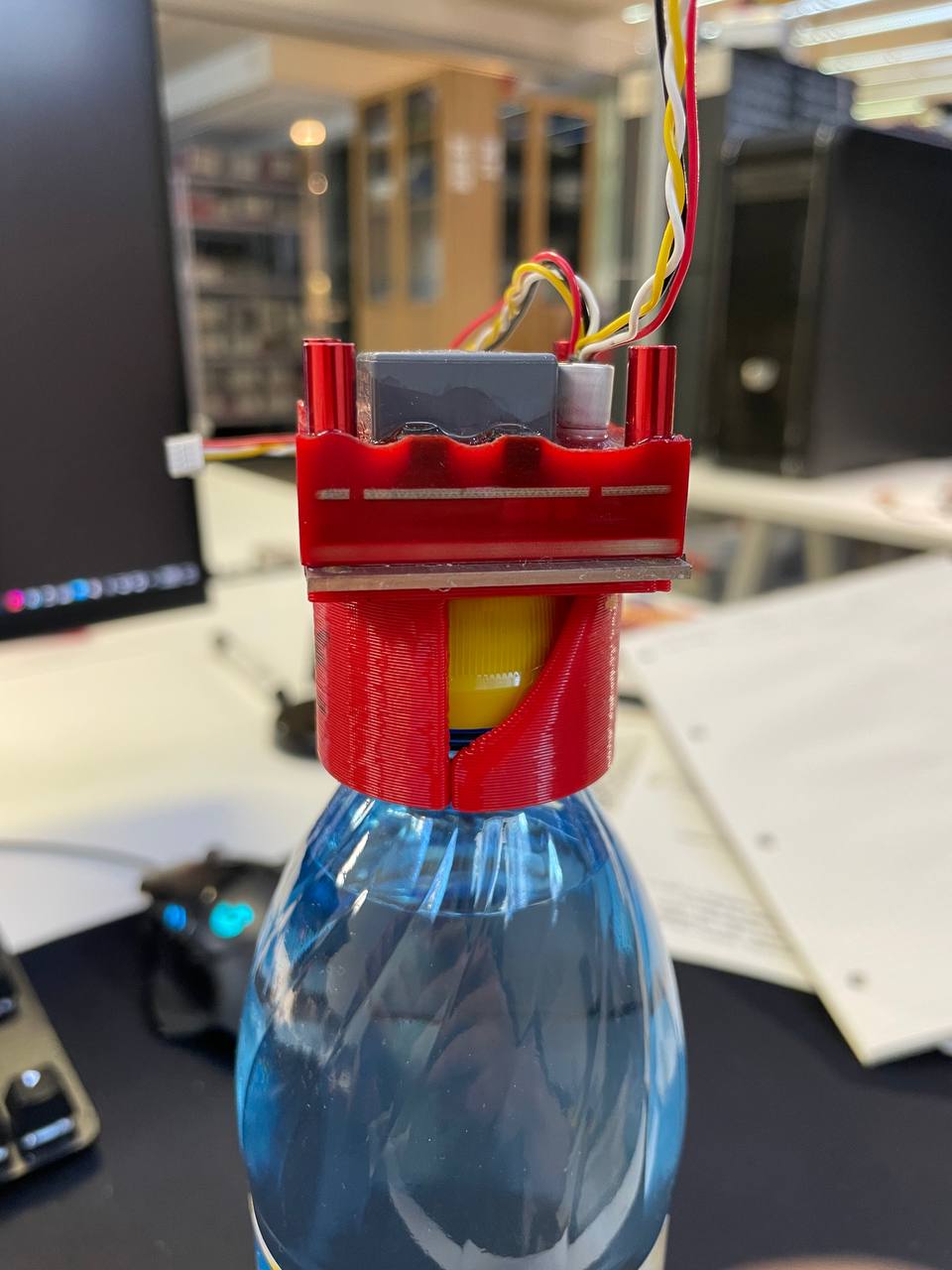

Bottle TeslaClaw demo¶

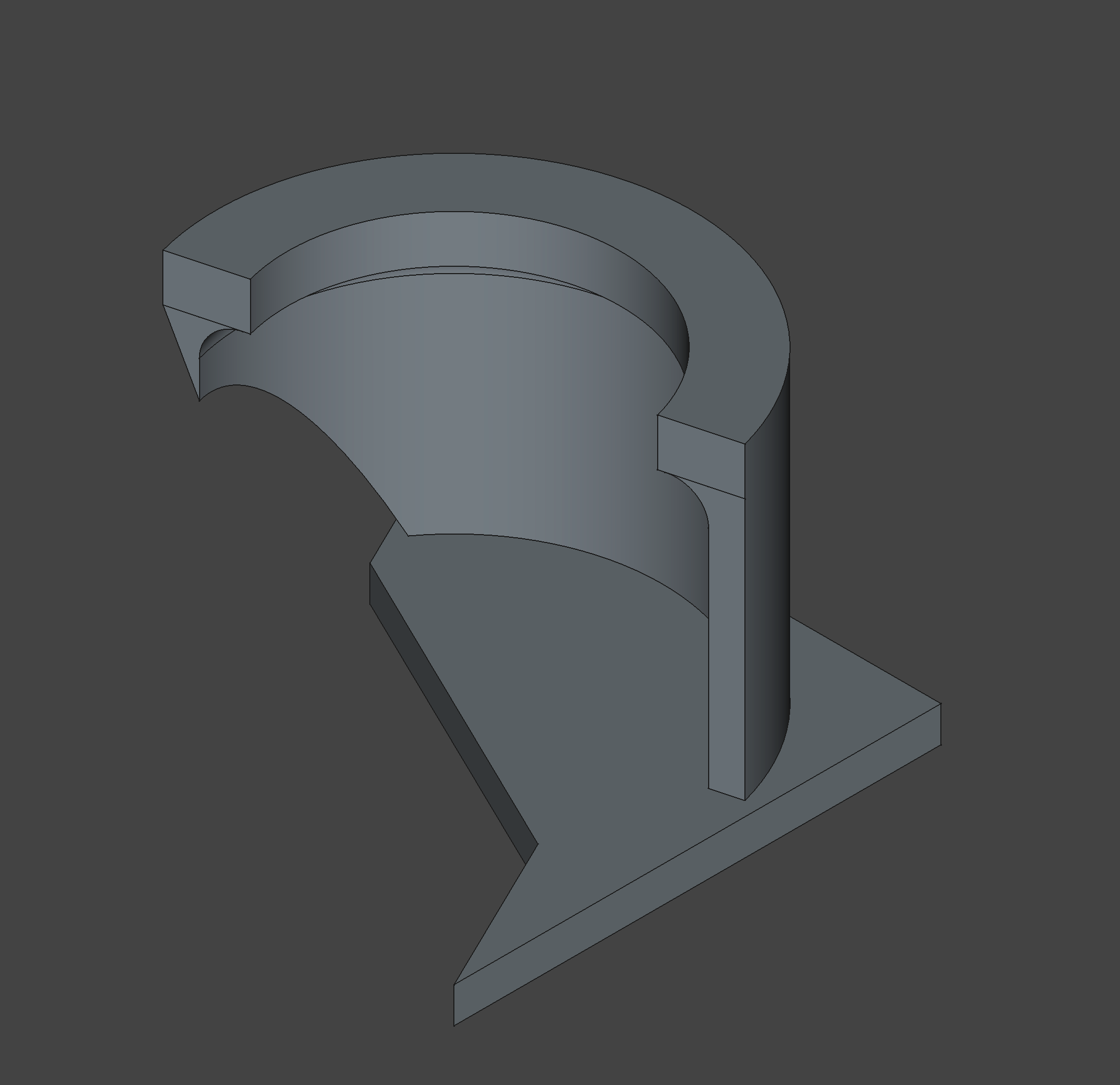

A simple demonstration of how to grip plastic bottles using an FG40-series EPM is introduced here. Following this example, one can trivially build an arbitrary custom adapter using a pair of low-carbon steel plates (e.g., AISI 1008, 1018, 1015) and two FDM-printed parts.

The TeslaClaw consists of two identical parts placed on opposite sides of the payload. Each part includes a steel plate that is attached to the magnet, and a plastic payload adapter that grips the payload. The plastic part is either glued to the steel plate or attached with countersunk screws. Alternatively, a more sophisticated design can be milled or laser-sintered directly from steel.

The built demonstrator is shown below in the relaxed and engaged states. In addition, the FreeCAD 3D model is shown for reference. A video is available on YouTube as well.

Notice that TeslaClaw is part of the magnet rather than the payload.

An attentive reader will notice that the two parts of the TeslaClaw are separated by a jagged edge rather than a straight one. This is an important design feature intended to induce disbalanced magnetization of each part, which creates a magnetic flux pulling the two parts of the adapter together.

Further, the line separating the two parts at the base is not parallel to the line separating them near the tip of the gripper. This design maximizes the gripping force in the presence of a transverse load.

The manufacturing cost of a single TeslaClaw as introduced here is less than 1 €.

Spring-loaded claw demo¶

The following video shows a slightly different approach, where FluxGrip is used to actuate a simple FDM-printed adapter claw. Credits: Scott Dixon